Richard M. Christensen |

||

|

||||

Recent Additons |

||||||

Key Junctures |

||

|

||||

General Matters |

||||

|

||||

|

||||||||

|

||||||||

|

||||||||

|

||||||||

Can Atomic/Nano Scale |

||||||||

|

||||||

|

||||||

|

||||||

|

||||||

|

||||||||

|

||||||||

|

||||||

|

||||||

|

||||||||

|

||||||||

|

||||||

Copyright© 2019 |

||||||

A Call To Service With Solid Mechanics

The case is made for the present and future revitalization of the discipline of materials failure, including needed educational reforms.

This is not a call to action, that would normally imply action for the sake of action. Service, in the present context, refers to an expansion of the knowledge base for the betterment of meaningful applications. The subject needing attention is that of materials failure and it is an immensely broad, inclusive and confusing area. The above title could well include the following subtitle: “The Status and Prospects for a Comprehensive Materials Failure Understanding”.

This is not a call to action, that would normally imply action for the sake of action. Service, in the present context, refers to an expansion of the knowledge base for the betterment of meaningful applications. The subject needing attention is that of materials failure and it is an immensely broad, inclusive and confusing area. The above title could well include the following subtitle: “The Status and Prospects for a Comprehensive Materials Failure Understanding”.

The Problem and Its Status

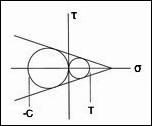

In order to proceed, failure criteria must be differentiated from fracture mechanics. Fracture mechanics is for application to the degrading effect of a dominant, controlling crack or notch existing in a structure required to bear load, regardless of scale of the structure, from exceedingly small to tremendously large.

The terminology and area of failure criteria is for the characterization of the inherent strength characteristics of homogeneous materials. This does not mean that there are no flaws or defects in the materials but rather that their distribution is itself homogeneous. High quality materials conform to this condition.

These two sub-areas of failure are completely complementary and both are very important. The operational status of the two disciplines is as follows:

- Fracture mechanics is a well established, mature discipline, it is extremely widely practiced and extremely helpful!

- Failure criteria as currently practiced is an undisciplined collection of empirical formulas of dubious value and uncertain applicability!

This document and proposition concerns the latter area, failure criteria. The development of failure criteria for isotropic materials has been stagnant and moribund for the past hundred years. Over the span of technical history nothing of lasting significance has been done to advance the field since the development of the Mises [1,2] and Tresca [2] criteria.

The attempted generalization of the Tresca criterion into the Mohr-Coulomb form [2] and the Mises criterion into the Drucker-Prager form [2] are superficial and misguided. The Tresca criterion itself is only a simple approximation to the Mises criterion. And the Mises criterion is only for proven application to highly ductile metals. The application of the Mises criterion to any other materials type gives results that are seriously in error. No failure criterion for all homogeneous and isotropic materials in any application has ever been found and brought into general use. In sharp contrast, fracture mechanics applies to all materials in all structures.

So there the discipline of failure criteria for general isotropic materials has remained since long before the modern era. It is in a state of suspension, completely misunderstood and sometimes carelessly and sometimes recklessly misapplied. It is time for a reversal of this absolutely unacceptable condition of the discipline at the center of required understanding for materials behavior.

Outlook and Education

While the failure characterization part of solid mechanics has stagnated the past many years, the companion field of fluid mechanics has flourished and amplified into major new understandings. Nominally this has been due to the development of computational fluid mechanics. But to imply that it is only due to new numerical techniques would be to greatly underestimate the fundamental advancements that have been made. The full range of fluid behaviors has greatly been broadened and deepened, especially toward the causation and treatment of turbulence with all its implications and complications. Fluid mechanics has thus come to grips with their most difficult, almost incomprehensibly difficult problem. Solid mechanics has done little or nothing with theirs.

All while this was happening with fluid mechanics, solid mechanics has remained stuck in place with no general advancements since that of fracture mechanics. The curricula in graduate courses reflects this situation. Fluid mechanics remains exciting and bursting with new developments and increasing enrollments. Solid mechanics has languished. A large part of this condition is due to the general premise that the solid mechanics/materials failure problems are too difficult to treat. There is a working consensus that these failure problems are so prohibitively difficult that they pose impenetrable barriers. It is this unfortunate stagnation that is in need of reversal through technical revitalization. Although the situation is approaching a state of being frozen in place, it still is not too late for final correction. But it will require a new and different consensus and movement from the technical community.

The most urgent need is to put a stop to teaching outdated and misleading views of materials failure. And this is nothing new, it has existed for a very long time. Apparently because of the endemic confusion, most books on mechanics of materials give only very brief treatments of failure criteria. Most materials science books also only give the slimmest possible description of the topic. The brief information that is usually imparted is completely, resolutely incorrect. The Mises and Tresca criteria are emphasized and left as being general criteria to be used for general purposes. Generations of engineers have been educated to believe that. This is a prescription for long lasting trouble. The few books that go beyond that naïve point of view do so by tacitly endorsing the Mohr-Coulomb and/or the Drucker-Prager criteria. This is even worse because it conveys an even stronger sense of generality that is completely misplaced. It is no wonder that the field of materials failure is misunderstood and misapplied in the work place where crucial decisions are made.

Continuing with this unfortunate circumstance, there is a compelling need to revise the failure treatments in materials science books and mechanics of materials books and in the tutorial aids used for teaching these subjects. Consequently there is an important and timely opportunity for new treatments and new editions of old books that remedy this enormous shortcoming in the tutorial mission. Both hard-cover and online books are needed. The change can only start at the true beginning, in the early stages of technical education.

Reform will not spring up from the design offices nor from the program developers. The methods and doctrines are solidified and hardened by that stage and largely unchangeable. A grass roots change is needed and it is at the early education stage where it must first begin to be implemented. In the past, ultra conservative design gave cover for many errors of omission and judgment. In the future, design will become a much more defined process with thinner margins. It will be necessary to design engineering materials applications to much stricter standards. There will be a responsibility to do so.

Future Possibilities

Certainly everyone is very busy. Is there time to step back from the personal programs that consume individual’s time and research efforts to confront this problem? Somehow the time must be found. There needs to be a new, stand alone, initiative for movement on the most difficult problems that are blocking advancement of the field, in this case solid mechanics. Solid mechanics is up against the obstacle of learning how to treat failure as a carefully constructed formalism with strict guidelines and not merely as an empirical exercise. If elasticity theory were treated as an empirical exercise one shudders to imagine what it would look like.

It is not expected that this change can or will come easily or quickly. The existing orthodoxy has been in place for far too long to allow that. Virtually all practitioners are comfortable with the simple, traditional (but incorrect) Mises and Tresca forms. The inertial resistance to change would be very great. The author’s generation have nearly all passed away, but this reform will not occur until after we all are entirely gone, and probably the next generation too. But now is the time to sow the seeds so that a healthy and mature change can come later. It is a technical and educational goal that must be undertaken by the forward looking technical community of the following generations. The time honored classical field of solid mechanics deserves no less.

A measure of perspective and history is appropriate at this point. The path is never easy or direct. Fracture mechanics was initiated by Griffith [3] in the early 1920’s. It was not until the 1950’s that Irwin [4] and others put it into a broadly usable form. Finally in the late 1960’s Rice [5] recast the entire fracture methodology into its most fundamental form. It all was a time consuming revolution in technical understanding, finally leading to rock solid and reliable technical applications. A second “revolution” is now needed in the way that materials failure (failure criteria for homogeneous materials) is understood and treated and applied.

It is not as though there is nothing to begin with for the second reformation in understanding to commence. In recent years the author has scouted and prepared a new book on materials failure, published by Oxford University Press [2]. Its content and direction are drastically, fundamentally different from anything ever given before. Additionally, References [6,7] expand and complete that work. Other investigators should also dig into the problem, perhaps even with diametrically opposed views and approaches, if they can substantiate a rational basis for it.

The entire field should be put under the critical microscope of examination, development, appraisal, and evaluation. The best work will survive and prosper and ultimately provide the basis for enlightenment and forward movement. In this connection, there should be a solid mechanics community effort to completely recast the teaching and practice of the discipline of materials failure. It will yield considerable benefits.

For those in the future who take up this call, they will be front line leaders at a high level of challenge and service for solid mechanics. The rigorous treatment of failure, when it finally does come into general use, will enable a great many new and decisive applications as well as complete a vital discipline.

References

- von Mises, R., 1913, “Mechanik der Festen Korper im Plastisch Deformablen Zustand,” Göttin. Nachr. Math. Phys., 1, pp. 582-592.

- Christensen, R. M., 2013, The Theory of Materials Failure, Oxford University Press, Oxford, UK.

- Griffith, A. A., 1921, “The Phenomena of Rupture and Flow in Solids”, Trans. Royal Society of London, A221, pp. 163-197.

- Irwin, G. R., 1957, Analysis of Stresses and Strains Near the End of a Crack Traversing a Plate,” Journal of Applied Mechanics, 24, pp. 361-364.

- Rice, J. R., 1968, “A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks,” Journal of Applied Mechanics, 35, pp. 379-386.

- Christensen, R. M., 2014, “Failure Mechanics-Part I: The Coordination Between Elasticity Theory and Failure Theory for all Isotropic Materials,” Journal of Applied Mechanics, 81, pp. 081001-1 to 7.

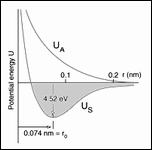

- Christensen, R. M., 2014, “Failure Mechanics-Part II: The Central and Decisive Role of Graphene in Defining the Elastic and Failure Properties for all Isotropic Materials,” Journal of Applied Mechanics, 81, pp. 111001-1 to 10.